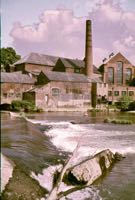

The Mill on the Exe, Bonhay Road

Formerly Head Weir Paper Mill

Page updated 11th April 2018

This pub and

restaurant occupies part of a

former

paper mill that was located just below Blackaller Weir. There had been

a fulling mill for processing wool

from at least the middle of the 16th century on this spot. It was let

in 1787 for milling corn and then in 1798, one Edward Pim started

paper making on the

premises. Edward Pim was related to the Pim family who ran an extensive

range of paper and grist mills at Barford and Bramshott, near Hindhead

in Surrey

between 1738 and 1832.

This pub and

restaurant occupies part of a

former

paper mill that was located just below Blackaller Weir. There had been

a fulling mill for processing wool

from at least the middle of the 16th century on this spot. It was let

in 1787 for milling corn and then in 1798, one Edward Pim started

paper making on the

premises. Edward Pim was related to the Pim family who ran an extensive

range of paper and grist mills at Barford and Bramshott, near Hindhead

in Surrey

between 1738 and 1832.

This description of the mill, and value, is from a 1799 insurance policy.

‘Edward Pim of the City of Exeter, Paper Maker. On his Paper Mills and store rooms, workshops and offices adjoining and communicating, stone brick timber and slated situated in the parish of St Edmund in Exeter aforesaid, known by the name of the Head Weir Water Paper Mills, having no kiln or steam engine in, adjoining or communicating £600. On millwright’s work £400. On stock in trade £1000.’

Royal Exchange Fire Insurance Policy 169180,

5 September 1799

Pim was however bankrupt by May 1814 according to

the

Flying Post and the following appeared "To be sold ... All those extensive paper

mills, capable of working 8

vats at one time, in which the paper manufactory has for many years

been carried on by Messrs. Pims ... situated near Engine Bridge".

In Coldridge's survey of 1818/19, it was noted as 'Mr Pim's Paper Mills

and Grist Mills'. It was quite common for mills to engage in

other activities,

probably at slack periods, and it was relatively easily for the

machinery to be converted from milling corn,

to milling bone or manganese, make paper or process wool. Head Weir

Mill does appear to have mostly made paper, with possibly some corn

milling. In the 1822/3 Pigot's, Robert Thomas is listed as a paper

maker at Head Weir while Joseph Ratcliffe is listed as a miller.

Both the paper and grist mill were for sale in 1829, when this advert appeared in the Flying Post.

‘Paper and Grist Mills for Sale. Head Weir Mills, situate near the Engine Bridge, in the City of Exeter.

Lot 1 consists of all those large and well-situated Paper Mills, comprising the drying lofts, engine house, two machine houses, store rooms, cellars, rag rooms, finishing room, and every other requisite for carrying on an extensive business. In addition to the stream of water, which is very powerful, there are four very large wells, at all times supplied with spring water which render these premises capable of producing the finest sorts of Paper. Contiguous to the aforementioned factory .. is a substantial, convenient and genteel Dwelling-House, comprising ..

A 48-inch machine, three engines, pumps, presses and other requisites may be taken by the purchaser at a valuation.

Lot 2 consists of all those capital Flour and Grist Mills adjoining the last lot, with three pairs of stones .. capable of grinding from thirty to forty loads of corn per week .. these premises are held under the above-mentioned Lease from the Chamber of Exeter.

A Cottage, comprising four rooms, nearly adjoining the Mills, calculated for the residence of a miller, will be sold with the Mills.’

Paper production was by Tremlett & Harris from about 1832, with the Tremlett family continuing to make paper at Head Weir until after the First World War. Charles Harris and his partner Edward Norish Tremlett invented a new process of production in 1836. The partnership was dissolved in 1844 with Harris moving to the Countess Weir Mill.

Edward Tremlett, was succeeded by William Tremlett who was reported as employing nine men. One woman employed at the mill was Sarah Chapman aged 94, and who is described as "assistant at paper mill". Paper mill workers were often forced to live in the most overcrowded and unsanitary areas of the city, with the Head Weir Mill drawing much of its labour from Exe Street; in 1851 nine paper workers lived in Exe Street. Strangely, these areas had a lower mortality rate than other parts of the city, which has been put down to the abundant fresh water available at the leats by the mills. Head Weir Mill drew its water directly from its own intake from Blackaller Weir which would have been untainted by effluent from the Longbrook that flowed into the Upper Leat just next to Head Weir Mill.

In June 1851, a House of Commons report noted that the mill had four working beating engines and one idle; 'Hollander' beating engines were used to separate the cellulose fibres in the rags to produce pulp. Only the paper mill at Trews Weir had more of these engines with six.

Fire and rebuilding

In 1882, the mill was badly damaged by fire requiring the building to be reconstructed out of brick, and the addition of a small Robey steam turbine which powered the mill when the water level was low. At the same time, a set of drying cylinders manufactured by Bentley and Johnson were installed. Just after the First World War, the mill was then taken over by E S & A Robinson of Bristol.

Much of the raw material for paper production was

from recycled waste paper and rag imported from overseas. Before the

mill closed

in July 1967, it was producing 50 tons of paper per week for tickets,

sugar paper and laminating. In 1982

the mill was demolished and Mill on the Exe reconstructed on the site

in 1983.

It is common to think that the pub inhabits part of the old mill

buildings, but the photograph of the partly demolished mill shows quite

clearly that the Mill on the Exe is

largely a reconstruction. It is also apparent that much of the car park

was mill-building before levelling. The lower floors of the pub suffer

from intermittent flooding, even

after the flood prevention scheme through Exwick was installed–that

last flooding was in October 2000, when the Mill on the Exe was forced

to close for a time to recover. In

time of flood, Blackaller Weir is a most impressive site, just below

the car park, and you may even see the flash of a salmon as it fights

its way up the river to spawn on

Exmoor.

Sources: The British Newspaper Archive, A H Shorter. Paper Mills and Paper Makers in England 1495-1800. Original documents, including a Royal Exchange Insurance Policy.

│ Top of Page │