- Home

- Memories

- Scrapbook ▽

- Topics ▽

- People ▽

- Events

- Photos

- Site Map

- Timeline

Page last updated 9 August 2009

Return to Industrial Exeter

The largest employer during

the late 19th and 20th

century in Exeter was Willey's Foundry of Water Lane. At their height

they employed over a 1000 workers, turning out the majority of gas

meters in the country. They also were an important producer of

munitions and equipment in both world wars. This important company in

the life of the city, for most of the 19th and 20th centuries, was

created by Henry Frederick Willey, a man from humble origins.

The largest employer during

the late 19th and 20th

century in Exeter was Willey's Foundry of Water Lane. At their height

they employed over a 1000 workers, turning out the majority of gas

meters in the country. They also were an important producer of

munitions and equipment in both world wars. This important company in

the life of the city, for most of the 19th and 20th centuries, was

created by Henry Frederick Willey, a man from humble origins.

Henry Frederick Willey was born in September 1830 to James and Mary Willey. James was a boot and shoe maker or what was known at the time, a cordwainer. The family were based in a poor part of St Sidwells, serving the locals from a small shop. The young Henry was sent to St John's Hospital School, leaving to join Vicary's, an Exeter manufacturer of equipment for the woollen industry and later for the burgeoning gas industry. The gas-meter was invented by Julius Pintsch in 1847 and Britain was taking advantage of this new technology.

When Mr Vicary died sometime in the 1860's, Henry Frederick Willey went into partnership with a Mr Ford and started Willey and Ford, based at Shilhay, as manufacturers of gas-stoves and gas-meters. It is very probable that the new partnership took over Vicary's business. The partnership did not last and within a short time, Willey was running Willey and Co. The factory did well and Willey became well known within Exeter, prompting him to enter local politics - in 1892-3 he was Mayor of Exeter, an Alderman and also a trustee of the St John's Hospital School. In December 1893, after visiting Pynes Water Works as chairman of the Water Committee, he developed asthma, and died on the 27th February 1894 at the age of just 64 years old, leaving £21,000 a not insignificant fortune for the time, and a healthy business for his son, Henry Alfred Willey. He was buried in St David's Churchyard, just by the footpath at Queen's Terrace.

H A Willey did not join the family firm immediately, but as a young man, attended Science and Art classes at the Exeter Museum, winning the Queen's prize for electricity and awards for chemistry, sound, light and heat. He then spent two years in South Africa, Australia, New Zealand, Egypt, Italy, Switzerland and France, advancing his commercial and technical knowledge. When he returned to England, he joined his father at Willey and Co.

When his father died in 1894, Henry Alfred took control and instigated a move of the foundry from their cramped, Shilhay premises, to Water Lane, Haven Banks. Within a short time, the young Henry Alfred Willey also expanded the meter manufacturing into new premises at James Street, off South Street.

Willey acquired the rights to Stephen Simpson's patented automatic meter, the first to employ coin-in the-slot payment, and business flourished. Soon the James Street premises became too small, requiring it move down to the Basin factory.

Henry Alfred Willey was a keen early motorist. In 1902, he purchased a car in Paris, drove it to the French coast and then after the crossing to Southampton, drove down to Exeter, no mean feat for the time. He is also credited with gaining permission to build the first private garage in Exeter from the Street Committee. Also in 1902, Henry Alfred Willey had talks with the Coventry Motor Company, with the aim of starting a motor manufacturing works in the city. It was planned that the company would produce 300 cars per year at a cost of £500 each - the projected set up cost of £47,500 to £65,000 proved to be too expensive and the project never happened. At his death at an early age of 41 in 1904, the family fortune had grown to £92,000.

"I worked for two years as a Patternmaker's apprentice from '66 to '68. It was a busy "shop", the pattern shop. I worked alongside Mick Came, Steve Lendon and Tony West whose dad worked in the office. My dad, Donald Dare was the Foundry chargehand, spending all his working life in the trade and being elected several times as Labour councillor for Whipton Ward. Both my uncles, Charlie and Harry Cropp worked in the foundry, pouring metal and fettling, or grinding off imperfections after casting. A Mr. Charlesworth, I think, used to brick up the insides of the furnaces, I think there were two for cast iron at the time. There were a lot of blokes of all descriptions there during the 60's, and we had a marvellous canteen up a dodgy wooden stair just around the corner of the patternshop run by a bloke with an enormous hooter called Ernie, - him, not the hooter.

Also, the most wonderful sports club just down water lane, made up of a couple of Nissen huts glued together. You could go there for a pint and a game of snooker. Willey's really did look after their employees, and you don't get this type of employment nowadays, where no-one's job is for life now.

I used to have pictures of my dad

sitting inside giant screws they used to cast for ships during the War."

Contributed by Chris Dare

By the early 20th century the company was producing everything from gas holders and meters, iron roofs and bridges. They had an enlightened attitude to their workforce and in 1903 started the in-house, weekly magazine 'Willey's Weekly - for Master, for Manager, for Man'.

Mr Willey wrote in one of the first editions "I have carried out some of the ideas which should make a straightforward workman's life a pleasure for him - profit sharing, manual education for boys, a band, ambulance corps, a paper of your own, the encouragement of invention, friendly societies, thrift, artisans dwellings, workmen's gardens, trams &c. ....... I shall never be content until I have doubled or trebled the number of workmen, increase their wages, proclaim an eight-hour day, give them houses to live in of their own and provide the aged and the infirm with old-age pensions".

Isca Road was the first council built estate in Exeter and dates from 1904 to 1907, on land donated by Henry Willey. There were forty two, red brick, work mens' dwellings for rent at a cost of 4 shillings and 9 pence per week (24 pence). Each house has a garden.

The First War saw Willey's employed in munitions work, making shells and fuel tanks for aircraft. For the first time, many workers were women, producing percussion caps, and castings of brass, iron and gun-metal.

Many of the foundry's workers came from the poor West Quarter and were only a short walk over the Exe Bridge from work. In the late 1920's and early 1930's, the West Quarter's slums were cleared and the population moved out to modern council housing in Burnthouse Lane. In 1935, Willeys constructed the Trews Weir pedestrian suspension bridge for their workforce in Burnthouse Lane to get to work.

During the Second World War they employed 1,300 including 400 women in their plants, manufacturing submarine equipment, and parachute containers, weapons and aircraft parts. The company were able to mobilise for war very quickly, as they brought much of the machinery used in the First War out of mothballs. The bombing of 1942, resulted in Willey's having its roof blown off and work continuing under the cover of 500 tarpaulins. During the preparations for D-day, Willey's were contracted to manufacture the large steel floating tanks for the Mulberry Harbour that were used on the Normandy beaches.

When the war was over, Willey's returned to their traditional products of gas appliances and general engineering work. Thornton Willey steered the company through the difficult post war years until his retirement in the 1950's. In November 1966, they were taken over by United Gas Industries and became a subsidery, with Mr A R Cason as managing directory.

On 22nd November 1980, it was announced that the engineering wing, which had produced so many gas-meters for the nation and on which the Willey's fortune was built, was to close down. However, the foundry continued to work and in 1981 a new facility designed to produce 6,000 tons of product per year, was opened at a cost of £250,000. This was a modernization that was too late to reverse their declining fortune, especially as their factory mostly consisted of a range of old fashioned and separate units. United Gas Industries closed the Water Lane plant down in the 1980's and the Willey's name was lost for ever, as an employer in Exeter.

It was in 1991 that the factory building in Water Lane, the place of work for so many Exonians, was demolished to allow the area to be developed. Apart from Willeys Avenue, and the Willey's Athletics and Sports Club in Water Lane, the one other reminder of the firm in St Thomas is the the Willey's family grave containing the remains of Henry Alfred Willey, which can be found in St Thomas Churchyard, and the grave of Henry Frederick Willey and his wife, Sarah Anne, in St David's Churchyard..

Sources: Express and Echo clippings and various web-sites © 2006/7 David Cornforth

Alderman

Henry Frederick

Willey, founder of the company. Photo from

Willey's Weekly

Alderman

Henry Frederick

Willey, founder of the company. Photo from

Willey's Weekly  Henry Alfred Willey ran the

company until 1904. He was one of Exeter's

earliest motorists.

Henry Alfred Willey ran the

company until 1904. He was one of Exeter's

earliest motorists.  Published in 1935, this

photograph shows casting at Willeys. The worker with the trilby was

Albert Henry Haynes Martin. Photo courtesy of Michael Martin.

Published in 1935, this

photograph shows casting at Willeys. The worker with the trilby was

Albert Henry Haynes Martin. Photo courtesy of Michael Martin.

Willey's

Meter Factory, Water Lane, now housing.

Willey's

Meter Factory, Water Lane, now housing.

Willey's Athletics and

Sports Club. Above photos courtesy of Aubone

Braddon.

Willey's Athletics and

Sports Club. Above photos courtesy of Aubone

Braddon. Willey's

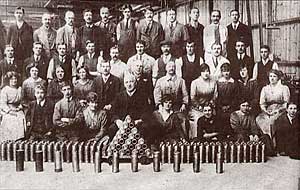

munition workers

in World War One.

Willey's

munition workers

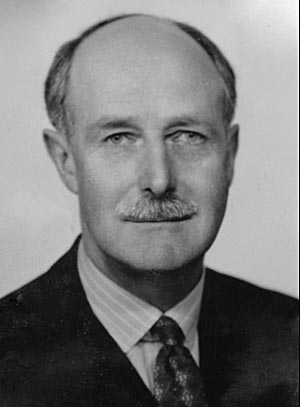

in World War One.  Thornton Willey,

1899 -

1975 took the company to the 1950's. Photo

courtesy of Benedict Willey.

Thornton Willey,

1899 -

1975 took the company to the 1950's. Photo

courtesy of Benedict Willey.

If you have a photo of Willey's Foundry, inside or out and would like to share it, please contact me on the email address at the foot of the page.

│ Top of Page │